New Roll-Forming Technology in 2025: The Future of Steel Frame Construction

The construction industry is constantly evolving, with innovative solutions being key to success. At U-Roof, we’re excited to announce that our investment in improved roll-forming capabilities will allow us to offer an enhanced range from January 2025. This breakthrough will make construction faster, more efficient, and sustainable.

In this blog, we’ll delve into what roll-forming is, its impact on steel frame production, and how it benefits various construction projects.

What is Roll-Forming and Why Does It Matter?

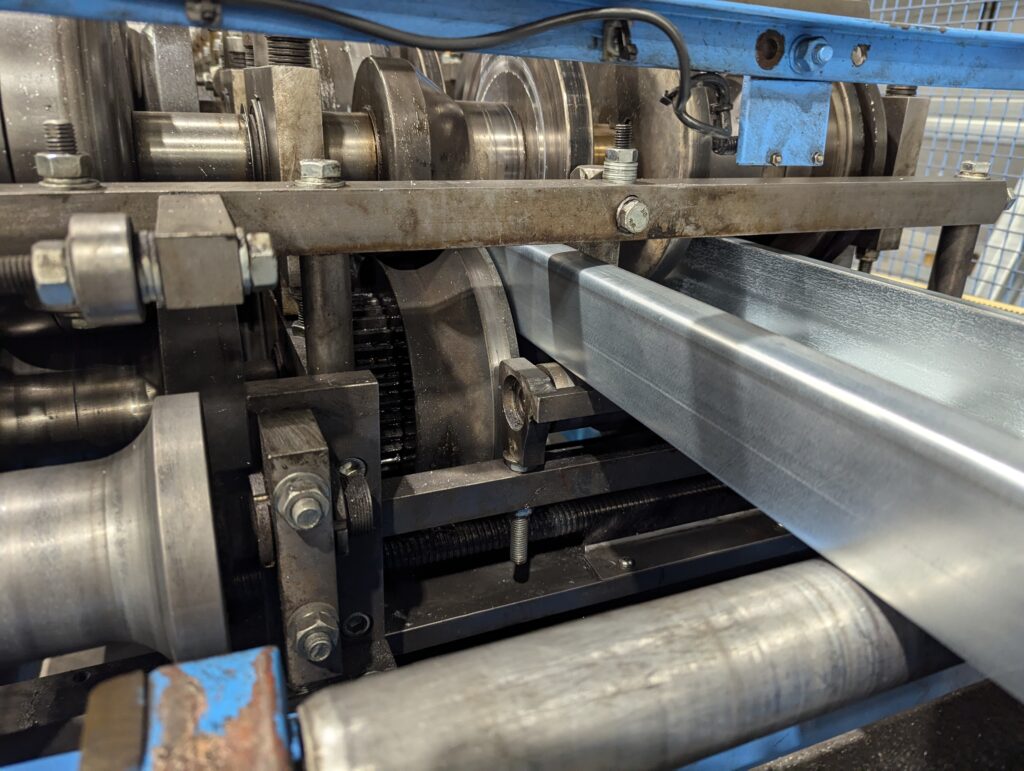

Roll-forming is a highly efficient, continuous manufacturing process that converts flat steel coils into various shaped profiles through a series of roller dies. These rollers gradually bend the material until the desired cross-section is achieved. Unlike other methods that may require heating, roll-forming is typically a cold-forming process, meaning it occurs at room temperature, which maintains the material’s natural strength and integrity throughout the process.

This process not only makes roll-forming cost-effective but also remarkably precise. By using a continuous flow of steel sheets, roll-forming can create consistent, uniform profiles over long production runs. This level of precision is critical in the construction industry, where structural integrity is a must. It ensures that the steel components fit together seamlessly during the assembly, reducing potential errors and delays during the build phase.

Why Roll-Forming Matters for Construction Projects

The advantages of roll-forming go beyond efficiency and precision. Here’s why it has become a preferred choice in modern steel frame construction:

- Consistency Across Components: Each pass through the rollers ensures that the steel profile maintains the same shape and thickness across the entire length. This uniformity is essential for creating strong, stable structures, as it guarantees that each frame piece will perform as expected under load.

- Reduced Material Waste: Traditional cutting or stamping methods often produce off-cuts, which can add to material costs and environmental waste. Roll-forming is designed to use only the required amount of material for each profile, making it an environmentally friendly choice for construction companies committed to sustainable building practices.

- Cost-Effectiveness: By reducing material waste, roll-forming helps control production costs. The ability to produce steel profiles continuously also reduces manufacturing time, enabling faster turnaround and lower labour costs. This cost-efficiency is passed on to builders and developers, making steel frame solutions more accessible.

- Enhanced Structural Performance: The process ensures that the material’s mechanical properties are retained or even enhanced, as the steel is gradually shaped without excessive stress or deformation. This leads to improved structural performance, making roll-formed steel frames ideal for both load-bearing and non-load-bearing applications.

- Customisation and Adaptability: The process allows for creating complex shapes that are difficult to achieve with traditional steel fabrication methods. It provides flexibility in design, making it possible to create bespoke profiles tailored to unique project requirements. From curved beams to intricate joints, roll-forming opens up new design possibilities for architects and engineers.

By incorporating advanced roll-forming technology, U-Roof is poised to enhance the production of steel frames, catering to a broader range of applications in residential, commercial, and industrial construction projects.

How Roll-Forming Enhances Steel Frame Construction

The new roll-forming capabilities at U-Roof bring several advantages to steel frame construction, making them ideal for residential, commercial, and industrial projects.

a) Faster Production Times

Roll-forming enables the manufacture of steel profiles more quickly than traditional methods. This efficient process means multiple profiles can be produced in one run, reducing manufacturing time significantly. This translates to shorter project timelines and more efficient resource usage.

b) Greater Design Flexibility

Roll-forming allows for the creation of complex profiles that are challenging to achieve with conventional methods. This means architects and designers have more freedom to explore unique structural designs, whether for a residential home or commercial building.

c) Enhanced Sustainability

As sustainability becomes a focus in construction, roll-forming supports this goal by minimising material waste. This efficient process only uses the steel needed for each profile, promoting a more eco-friendly building approach.

Still wondering if roll-formed steel frames are the right choice? Here are five reasons why this technology will redefine the future of construction.

5 Reasons to Choose Roll-Formed Steel Frames with U-Roof

- Cost Efficiency: Roll-forming reduces production costs by maximising material use and minimising waste, making steel frame solutions more affordable for a variety of projects.

- Improved Structural Integrity: Profiles produced through roll-forming have consistent thickness and strength, ensuring greater stability and safety in construction.

- Customisable Designs: With the ability to produce bespoke steel shapes, U-Roof can meet specific project requirements, making it ideal for both standard and bespoke builds.

- Faster Lead Times: The efficiency of roll-forming shortens production timelines, helping projects stay on schedule.

- Eco-Friendly Construction: By reducing material waste, roll-forming supports sustainable building practices, making it the right choice for environmentally conscious projects.

What to Expect from U-Roof’s Roll-Forming Launch in 2025

As U-Roof gears up to launch its roll-forming capabilities in 2025, clients can expect several advantages:

- State-of-the-Art Technology: Our new cutting-edge machinery ensures consistent precision and efficiency for every profile produced.

- Expert Guidance: Our team will offer professional support to help clients integrate roll-formed frames into their projects seamlessly.

- Expanded Offerings: With roll-forming, we’ll provide a wider range of steel profiles, tailored to meet various construction needs, from homes to large commercial builds.

U-Roof’s roll-forming launch represents a leap forward in steel frame construction, offering faster production, greater design flexibility, and enhanced sustainability. As we prepare for this exciting launch in 2025, we invite builders, developers, and architects to explore the possibilities of roll-formed steel frames.

If you’re considering roll-formed steel frames for your next project, contact the U-Roof team. Our experts are ready to guide you through the process, offering solutions tailored to your construction needs.